Providing products that meet customer needs using the knowledge and experience gained through our long history.

If special packaging is required, we can develop and provide packaging machines to meet customer needs.We install equipment to match space within the factory as well as production processes.Combining our knowledge and experience gained through our long history gives us flexibility in making proposals.

Product category:Cup Filling And Capping System

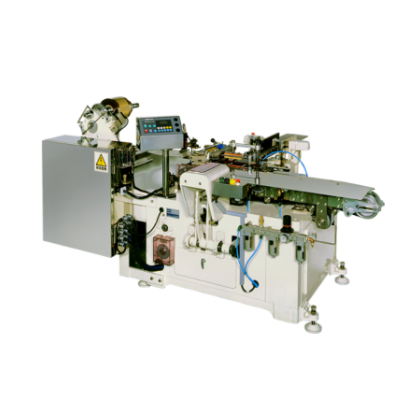

KBF-3KHG/3KHN Vertical Packaging Machine

Ideal for filling and packaging of paste products and powdered products, including miso. KBF-3KHG of gusset specification with hem is also available.

Product features

-

01

fill machine for the paste product which is sticky

Micro computer control digital display method enables the easy operation.

-

02

Self-diagnosis function

Self diagnostic function enables to display the error part and to recover quickly by the emmidiate machine stop.

-

03

Easy to fine-tune

It can easily adjust the gram of the filling machine electicaly, while box casing.

-

04

Special air vent

Special air vacuume device takes away most of the air inside the package.

-

05

Changing the filling quantity

Auto amount change device(optional)enables the automatic changing of filling amount (ex:500g and 1kg).

-

06

Optional change of packaging speed

Inverter is installed standardly so you can set the filling amount, production amount, each condition, packaging speed arbitary.

Purpose

Miso, surimi, powder, mayonnaise, bean paste, sake meal and other mucilage, powders, kneads, etc.

Specification

-

Type

type-500g/type-1kg/type-1.5〜2kg

-

Capacity

[type-500g] 35~40rpm

[type-1kg] 30~35rpm

[type-1.5〜2kg] 20~25rpm -

Bag size

[type-500g]

Length:200mm/Width:125mm/Height:-[type-1kg]

Length:240mm/Width:155mm/Height:-[type-1.5〜2kg]

Length:300mm/Width:200mm/Height:- -

Packaging materials

NY/PE

-

Machine dimensions

(H)3,040mm×(W)1,270mm×(L)1,600mm

※Only main for 1kg -

Weight of machine

Approx.1500kg

-

Power consumption

3phase 200V

Motor:2.7Kw

Heater:1.6Kw

Compressor:3.7Kw(5HP)

Other:0.2Kw -

Air consumption

0.6MPa 400NL/min(35rpm)

Product category:Cup Filling And Capping System

CSA Cup Filling And Capping System

Cup cap closure machine CSA - 20 (4-piece disks for general purpose type) and CSA - 41 (high speed type for 6discs ) are auto capping closure machine to feed parchmen, oxygen absober, and upper sheetin automatic or manually feeding containers.

The filling machine CSA - 60 (3 axis servo control type) is a cup filling machine that automatically performs cup supply, cup dust collection, and filling paste to the cup.

Product features

-

01

Have excellent dual use

(CSA-20・41)

It is superior in dual use, and it can be used for 300, 500, 750g and 1kg by 10-15 min parts replacement. -

02

Color touch panel

(CSA-20・41)

It is easy to operate with colour touch panel. -

03

The space-saving design

(CSA-20・41)

There will be no trouble for the installing location with the extremely space-saving design. -

04

Clean filling

(CSA-60)

You can set a clean filling regardless of the characteristic of the viscose by the servoed cup pushing uphead. -

05

Automatic adjustment

(CSA-60)

Automatic adjustment such as changing filling amount can be done, and it can register 30 types of product code. -

06

Layout that matches the space

(CSA-60)

Even if it is line systemed with the cup closing machine, layouts according to the factory spae is possible.

Purpose

Paste,Ground Fish,Powder,Other Liquid, Paste, Powder, Fishery and Bulk Products

Specification

-

Type

Cup cap closure machine/Filling machine

-

Model name

[Cup cap closure machine]

CSA-20(4-piece disks for general purpose type)

CSA-41(high speed type for 6discs)[Filling machine]

CSA-60 -

Capacity

[CSA-20] 15~20pcs/min.

[CSA-41] 20~28pcs/min.

[CSA-60] 20~28pcs/min. -

Dual use range

300g/500g/750g/1kg

-

Cup size

Length:145〜100mm/Width:135〜100mm/Height:90〜70mm

-

Standard accessory

[Cup cap closure machine]

Perchment feeding device,Shachet applicator,Upper sheet infeed device,Capping device[Filling machine]

Cup Infeed device,Cup vacuum,Filling Device -

Machine dimensions

[CSA-20]

(H)1,820mm×(W)1,050mm×(L)2,080mm[CSA-41]

(H)1,820mm×(W)1,150mm×(L)2,010mm[CSA-60]

(H)1,470mm×(W)1,170mm×(L)2,440mm -

Weight of machine

[CSA-20] Approx.640kg

[CSA-41] Approx.750kg

[CSA-60] Approx.600kg -

Power consumption

[Cup cap closure machine]

3phases 200V 2,000W[Filling machine]

3phases 200V 3,000W -

Air consumption

[CSA-20] 360NL/min(5kgf/㎠)

[CSA-41] 600NL/min(5kgf/㎠)

[CSA-60] 90NL/min(5kgf/㎠) -

Option

[Cup cap closure machine]

■even sheet type, gas valve can be applied with LV-1(CSA-41A)

In stead of sheet, apply roll type film for cost save.

CSA-41AS can be applied both sheet and roll type.

■Gas Valve applicator.

Piercing Upper Sheet /Roll paper and apply gas valve.

Even sheet type, gas valve can be applied with LV-1

■Cap feeding double type

■Rejector(Metal detector,Feeding,Upper label sealing NG etc.)[Filling machine]

■Sanitary Type filler(CSA-65)

Easy disasemble from hopper to outlet nozzle for sanitary.

Hopper hight is just around weist, so that it is easy to refill.

■Filling amount auto changing device.

Along with product memory code, fillin gamount can be changed automatically

■Feed back control

Weight trendcontrol from signal of a weight checker

■Cup feeding double type and ,Cup feeding multi lanes

■Metal detect at Filler nozel.

■Rejector (weight,Metal detector)

Product category:Cup Filling And Capping System

GW-3145 Over Wrapping Machine

This one unit will also use packaging of "Miyabi fold", "Fukusa twist", "Pinch fold " suitable for traditional luxury Japanese confectionery.

Product features

-

01

Three Types of "japanese style" overwrapping by one machine

The product will look as though it has been beautifully hand wrapped with heart.

-

02

Product individualization

According to your request, the top of wrapping can be one point label sealed. It enables to personalize the product.

-

03

Beautiful packaging

Special device has been done to wrap fresh and semi-baked confectioneries, soft and fragile products beautifully.

Purpose

Manju,Bean‐Jam‐Filled Wafers.,Rice Cake,Gyuhi,Mashed Sweet Potatoes with Sweetened Chestnuts,Product in Tray,Cupcake,Crunchy Chocolate,Other confectionery(Relatively Soft Products)

Specification

-

Packaging form

Miyabi Fold, Fukusa Twist, Gassho Fold

-

Type

Round Shape

-

Capacity

40~50pcs/min.(depending on conditions.)

-

Size range of the package

◇Round Shape

Size:φ30~70(Round)/Thickness:25~40mm/Length:- -

Standard accessory

Photo censor,Product detect Photo sensor,Dual Film roll stand,Film end,Centerized lubrication,Heater micom control

-

Packaging materials

Moisture Proof T.C.,Paper Poly

-

Wrapping diameter

Max.φ280mm(Inner Core φ75mm)

-

Paper size

120mm〜170mm

-

Machine dimensions

(H)1,440mm×(W)1,825mm×(L)2,260mm

-

Weight of machine

Approx.980kg

-

Power consumption

Motor:3phases 220V 400W(1/2HP)

Heater:15W(Discharge)

Point:150W x 2 -

Separate specification

Extra Former A'ssy・Others,Depending on requests.

-

Option

Date Printer,Labellor,Auto feeding machine etc.

Product category:Cup Filling And Capping System

GW-45 Over Wrapping Machine

It is a revolutionary packaging machine mechanized the "Fukusa twist packaging" that increases added value of products.

Product features

-

01

Packaging Japanese culture "Wa"

It can only be done in our original machine.

-

02

Gentle packaging

Not only it can gently wrap "sweet bun" and "soy jam wafer" but also some soft products such as "rice paste".

-

03

Gentle packaging

By changing the parts, it can wrap different product.

-

04

Joint folding packaging is also possible.

Depending on the charactoristic of the product, you can choose fin fold wrapping.

-

05

Graceful packaging

It is elegant package style looks like hand wrapped.

Purpose

Manju,Bean‐Jam‐Filled Wafers.,Rice Cake,Gyuhi,Mashed Sweet Potatoes with Sweetened Chestnuts,Product in Tray,Cupcake,Tenmusu,Crunchy Chocolate,Other confectionery(Relatively Soft Products)

Specification

-

Packaging form

Fukusa twist

-

Type

Round Shape/Square Shape/Rectangular Shape

-

Capacity

40~50pcs/min.

-

Size range of the package

◇Round Shape

Size:φ30~50(Round )/Thickness:15~35mm/Length:-◇Square Shape

Size:□30~50(Corner)/Thickness:15~35mm/Length:-◇Rectangular Shape

Size:30~50(Width)/Thickness:15~35mm/Length:30~60mm -

Standard accessory

Film economizer,Photo censor,Film end,Jackbolt

-

Packaging materials

Moisture Proof T.C.,Paper Poly etc.

-

Wrapping diameter

Max.φ280mm(Inner Core φ75mm)

-

Paper size

110mm〜165mm

-

Machine dimensions

(H)1,440mm×(W)1,150mm×(L)1,830mm

-

Weight of machine

Approx.850kg

-

Power consumption

Motor:3phases 200V 400W

Heater:300W

Others:Approx.150W -

Option

Date Printer,Auto feeding machine,Paper inserting Device. etc.

-

Annotation

Extra Former accessory,Others,Depending on requests.

Product category:Cup Filling And Capping System

GW-50 Over Wrapping Machine

We have mechanized the "HOUSYO folding packaging" which raises the value of confectionery by tradition and formal style.

Product features

-

01

Traditions and elegance

Packaging the Japanese tradition and formality.It is an epoch-making machine only available in KAWASHIMA.

-

02

Gentle packaging

It enables to wrap the product gently by the unique mechanism.

-

03

Luxurious packaging

It is a luxurious packaging looks as it is hand wrapped.

Purpose

Pie Manju,Habutae Mochi,Bean‐Jam‐Filled Wafers.,Sandwich Rice Cracker,Yubeshi,Sweet Red Bean Paste(Anko),DryConfectionery,Rakugan,Sweet Rice Jelly,Undried Cake,Cookies,Fish Paste,Other confectionery(Relatively thin products) etc.

Specification

-

Packaging form

HOSYO fold

-

Type

Round Shape/Square Shape/Rectangular Shape

-

Capacity

35~40pcs/min.

-

Size range of the package

◇Round Shape

Size:φ40~70(Round )/Thickness:8~35mm/Length:-◇Square Shape

Size:□40~70(Corner)/Thickness:8~35mm/Length:-◇Rectangular Shape

Size:30~70(Width)/Thickness:8~35mm/Length:40~75mm -

Standard accessory

Film economizer,Film End,Photo Sensor

-

Packaging materials

HOUSYO paper(50~60g/㎡),Laminated Paper(35~50g/㎡),Chemical fiber paper(30~50g/㎡) etc,Film Thickness15μ is the base.

※Depending on film materials, it may be conditional or special specification.

-

Wrapping diameter

Max.φ280mm(Inner Coreφ75mm)

-

Paper size

(W)120~210mm×(L)150~200mm

-

Machine dimensions

(H)1,280mm×(W)1,290mm×(L)2,530mm

-

Weight of machine

Approx.630kg

-

Power consumption

Motor:3 phases 200V 200W

Others :Approx.100W(In case of Point seal application 150W) -

Separate specification

For Size chage,prior review is required. Depending on requests.

Product category:Cup Filling And Capping System

GU-211MC Over Wrapping Machine

Automatic overwrapping packaging machine for folding kamaboko in Chocolate bar base fold.

Product features

-

01

Easy operation with switch

Uses LCD(liquid crystal display) backlighting on the display section and each indication has an independent switch which makes the operation easy.

-

02

Store packaging data

You can store 9 kinds of data for each product to be packaged. Just by specifying the product code, it will automaticallyset the paper length, timing of each function, temperature set value.

-

03

Microcomputer control

Heater temperature can be set/changed by controlling micro computer.

-

04

Self-diagnosis function

It has a self-diagnosis function. When an abnormality is detected, the buzzer sounds and the machine stops automatically. This abnormality content will be displayed on the LCD.

-

05

Display necessary data

The micro computer stores each data and displays necessary data. Volume(amount of product), speed, paper length(reg ark, plain), heater temperature, package material usage, operation time will be displayed.

-

06

Improved finish of the insertion part

The finish of folding part(product length, small part)has become more beautiful than the conventional machine.

-

07

With minimum manual lubrication points

By installing the oil type central lubrication system, the manual lubrication point became minimized.

Purpose

Kamaboko,Raw Kamaboko※ etc.

※The model name is GU-211RMC if you would like to pack Raw Kamaboko.

Specification

-

Capacity

40~60pcs/min.(Depending on the products and other conditions.)

-

Size range of the package

Length:100〜180mm/Width:37〜75mm/Height:30〜50mm

-

Dual use range

Length:Max 50mm/Width:Max 30mm/Height:Max 25mm

-

Packaging materials

OPP(25~40μ),Rayon Paper

-

Wrapping diameter

500~1,000m roll(Max.φ280mm)

※Varies depending on the packaging material. -

Paper size

(W)155〜240mm×(L)210〜300mm

-

Machine dimensions

(H)1,220mm×(W)2,025mm×(L)1,900mm

-

Weight of machine

Approx.750kg

-

Power consumption

Machine:3 phases 220V 400W(1/2HP)

Heater:220V 400W(3pcs)

Film Feeed Motor:220V 25W(2pcs)

※In case of Kamaboko wrapping,Compressor 3 phases220V 750W(1HP)is required. -

Air consumption

GU-211RMC only.(It depends on the packaging conditions.)

-

Option

Date Printer,Dual film roll stand etc.

Product category:Cup Filling And Capping System

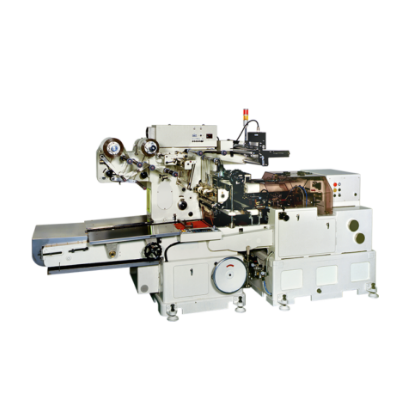

RKW-101MC Over Wrapping Machine

It is an automatic overwrapping packaging machine for small folding of raw kama.

Product features

-

01

Hygienic

It enables to wrap fresh Kamaboko without being touched by a hand(synchronizes with the plate forming auto cutter)

-

02

Perfect tight-fitting small-mouth folding

It will completely closefit smallfold small fold with the developped special folding guide.

Therefore it has the maximum effect with the minimum use area of packaging material. -

03

Maintain freshness

Freshness at the time of manufacturing can be maintained for a long time.

-

04

There is no loss of packaging material.

There will be no loss of packaging material by the function of the waste paper prevention device.

-

05

Prevention of pattern deviation by option

With the option of optoelectronic device(registration controller type), the deviation of the printed pattern will be corrected automatically.

In addition, it is possible to separately install a date printing device and double wrapping device. -

06

Special packaging

Caution: Special packaging material for the fish paste shall be used for the inner wrapping.

-

07

Packaging of bat confections

You can also wrap japanese confectionery "Saomono" by custom-made.

Purpose

Raw Kamaboko,Confectionery※

※Please consult with us in advance if you would like to pack confectionery product with the machine.

Specification

-

Capacity

25~70pcs/min.(Depending on the products and other conditions.)

-

Size range of the package

Length:110〜160mm/Width:30〜60mm/height:30〜60mm

※Length is Special application 62~105mm -

Dual use range

Length:Max 40mm/Width:Max 15mm/Height:Max 15mm

-

Packaging materials

KIC,Gardron(R)

-

Wrapping diameter

500~1,000m roll(Max.φ280mm)

-

Paper size

Max(W)240mm×(L)245mm

-

Machine dimensions

(H)1,170mm×(W)1,920mm×(L)2,065mm

-

Weight of machine

Approx.1,200kg

-

Power consumption

Machine:3 phases 220V 400W(1/2HP)

Heater:220V 1,560W(total)

Others:100W

Compressor:3 phases 220V 2,200W(3HP) -

Air consumption

0.4Mpa 110L/min(In 60rpm)

-

Option

Date Printer,Photo censor. etc.

Product category:Cup Filling And Capping System

SRK-200 Over Wrapping Machine

Packing machine famous as wrapping Swiss rolls.

Product features

-

01

Microcomputer control

Micro computer enables to memorise and display each product data (product name, production amount, machine speed, film length, heater temperature, film use amount, operation time) maximum 10 types product.

-

02

Adjustment of paper length is unnecessary.

Servo driven film feeding relieves you from adjusting the film length for each product.

-

03

Precise temperature control

Heater temperature control will be done against each product code by the micro computer accurately.

-

04

Troubleshooting

When there is a trouble the machine will stop automatically and show the error detail.

-

05

Easy operation with switch

Each function has independent switch so its easy to operate.

-

06

Easy operation with switch

Date printer and labeler can be attached as an option.

Purpose

Swiss Roll

Specification

-

Capacity

25~35pcs/min.

-

Type

Round Shape/Square Shape

-

Size range of the package

◇Round Shape

Length:100〜240mm/Width:φ50~90(Round)/Height:-◇Square Shape

Length:100〜240mm/Width:55〜95mm/Height:50〜80mm -

Standard accessory

Photo censor,Ceterized Lubrication,Film End Detect

-

Packaging materials

Moisture Proof T.C.,KOP,Aluminum Poly coat. etc.

-

Wrapping diameter

Max.φ300mm(Inner Coreφ75mm)

-

Paper size

(W)220〜380mm×(L)210〜320mm

-

Machine dimensions

(H)1,810mm×(W)1,585mm×(L)3,500mm

-

Weight of machine

2,400kg

-

Separate specification

3phases 200V Approx.2.8kW 20A

-

Air consumption

500KPa 25L/min(In 35rpm)

-

Option

Date Printer,Labellor etc.

- 01 Vertical Packaging Machine

-

KBF-6000UXR Vertical pillow packaging machine KBF-6000UX Vertical pillow packaging machine KBF-6000X Vertical Packaging Machine KBF-6000XR High Speed Vertical Packaging Machine KBF-6000Xe Vertical Packaging Machine KBF-6000XeD Vertical Packaging Machine KBF-6000XeR High Speed Vertical Packaging Machine KBF-6000XG Vertical Packaging Machine

- 02 Horizontal Packaging Machine

-

KBF-7000V2 Horizontal Form Fill Seal Machine KBF-7000V Horizontal Packaging Machine KBF-7500V Horizontal Packaging Machine – Film bottom load KBF-700e Horizontal Packaging Machine KBF-750e Horizontal Packaging Machine -Film Bottom Load- GW-7 Horizontal Packaging Machine KBF-74000ZⅡ Four side seal zipper packaging machine

- 03 Overwrapping Machine

- 04 Auto-Caser

- 05 Cup Filling And Capping System